Roller Compactor (Dry Granulation)- flexible and highly efficient:

Reliable Dry Granulation Solutions for the Pharmaceutical Industry

A Pharmaceutical Roller Compactor is a critical machine used for dry granulation, where powders are densified and converted into uniform granules without the use of liquid binders or a drying step. This technology is widely adopted in pharmaceutical manufacturing, especially for formulations that are sensitive to heat or moisture.

At Systems BD, we supply and support high-quality roller compaction solutions suitable for R&D, pilot scale, and full-scale pharmaceutical production.

What Is Dry Granulation?

Dry granulation is a process in which fine powders are compacted between two counter-rotating rollers to form flakes or ribbons. These compacted materials are then milled into granules with controlled particle size distribution.

Unlike wet granulation, dry granulation:

- Does not require water or solvents

- Eliminates the drying process

- Preserves API stability

- Reduces overall processing time and energy consumption

This makes it an ideal solution for modern pharmaceutical manufacturing.

How a Roller Compactor Works

A typical pharmaceutical roller compactor consists of:

- A controlled feeding system

- Two precision rollers that apply uniform compaction force

- A flake or ribbon forming zone

- An integrated milling unit to produce granules

Key process parameters such as roller pressure, roller speed, gap setting, and feed rate allow precise control over granule density, size, and flow properties.

Key Benefits of Pharmaceutical Roller Compaction

- No moisture or heat exposure – ideal for sensitive APIs

- Improved powder flowability – better downstream processing

- Consistent granule quality – uniform bulk density and size

- Reduced dust generation – safer and cleaner operation

- Scalable process – from laboratory trials to commercial production

Typical Applications:

Pharmaceutical roller compactors are widely used for:

- Tablet and capsule formulations

- Dry granulation of APIs and excipients

- High-potency and low-dose formulations

- Formulations with poor flow or compressibility

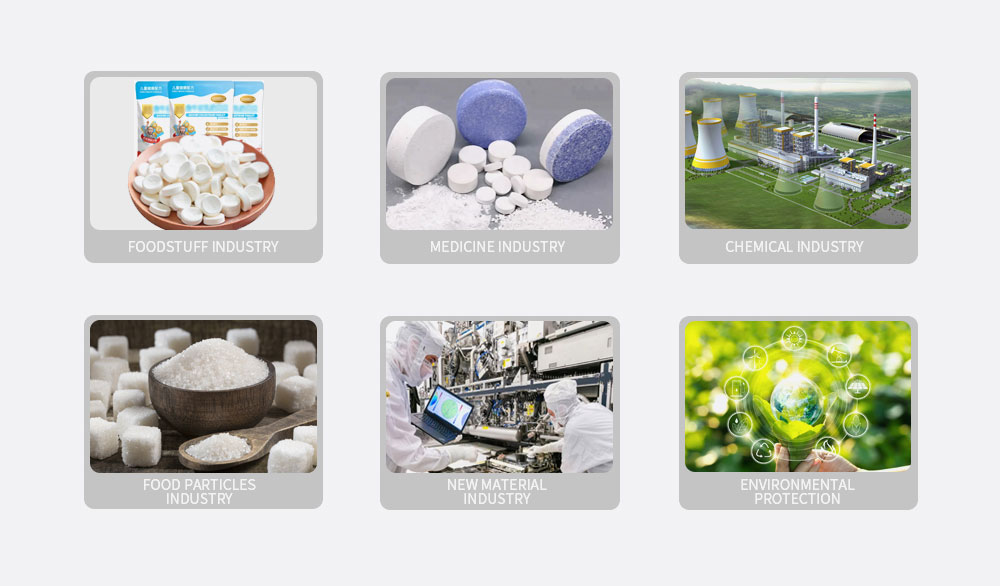

They are suitable for industries including:

- Pharmaceutical

- Nutraceutical

- Chemical and specialty materials

Design Features for Pharmaceutical Use:

Hygienic & GMP Design

- Stainless steel product contact parts

- Smooth, easy-to-clean surfaces

- Wash-in-Place (WIP) or easy dismantling options

Process Control & Automation

- Precise control of roller force and gap

- Consistent start-up to minimize material loss

- PLC-based control systems with recipe management

Containment – No Compromise on Safety

With the development of new pharmaceutical products, active pharmaceutical ingredients (APIs) are becoming increasingly potent. In many markets, the high-potency active pharmaceutical ingredient (HPAI) segment is growing at a double-digit rate, largely driven by oncology therapies.

Beyond compliance with manufacturing guidelines, ensuring operator safety and patient protection is critical. As a result, pharmaceutical manufacturers face increasing challenges across all toxicity classes when designing and operating processing equipment.

To address these demands, a dedicated containment configuration designed for OEB 5 applications is available as a representative example.

Key Features of the Containment Roller Compactor

- Integrated isolator within the compaction unit, including continuous vacuum monitoring

- Glove box with interlocked safety system for controlled flake discharge

- Containment port for safe flake sampling

- Containment port beneath the sieve unit for contained granule discharge

- Enhanced accessibility, as full enclosure of the entire compactor is not required

- Residue-free product discharge supported by an integrated wash-in-place (WIP) system

(WIP is also available in the standard configuration)

- ATEX-compliant designs where required

Scalability & Flexibility:

Roller compactors can be selected to match different production requirements:

- Laboratory & R&D scale – formulation development and trials

- Pilot scale – process optimization and validation

- Production scale – continuous, high-throughput manufacturing

This scalability ensures smooth technology transfer from development to commercial manufacturing.

Why Choose Systems BD:

Systems BD is an engineering-focused solution provider with strong experience in pharmaceutical process equipment. We support our customers throughout the project lifecycle:

✅ Technical consultation and equipment selection

✅ Process understanding and capacity matching

✅ Installation, Validation & Training

✅ Regulatory Compliance (GMP, FDA, EMA)

✅ Local Service, Global Standards

Our goal is to deliver reliable dry granulation solutions that fit your process, product, and regulatory requirements.